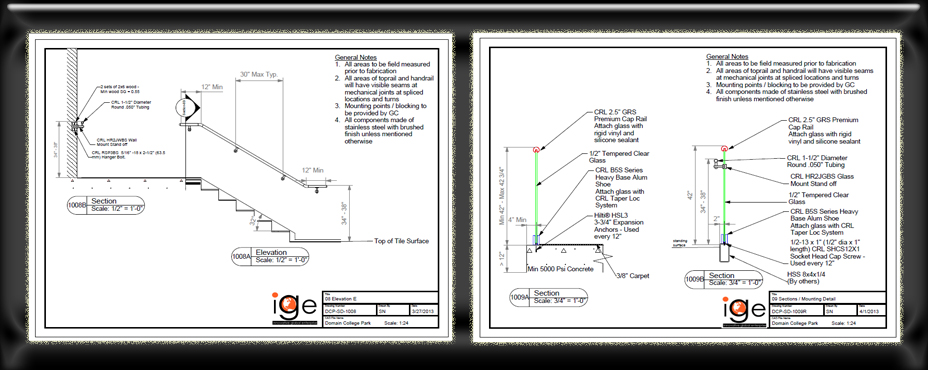

Our featured project on the month is glass and stainless steel railings installed at University of Maryland – Domain College Park. Domain College Park is a U.S. Green Building Council LEED certified community and features brand new one bedroom and two bedroom apartments for rent in College Park, MD at the University of Maryland. The glass railing in the lobby area while serving as a guard against fall provides clear and unobstructed views of the building. The railings pass building code and are also a beautiful accent to this project. A heavy aluminum base shoe is attached to the substrate (steel stringer) with approved anchors. ½” thick, tempered glass panels are installed using compressed tapers using the dry-glazing system. A brushed stainless steel top rail is mounted on the glass rail with vinyl insert and some silicone. Glass mounted handrail brackets are installed on pre-drilled holes in the glass balusters. Handrail is aligned and positioned and mechanically attached to the brackets. Wall mounted hand-rail brackets are also installed on the other side of the stairs.

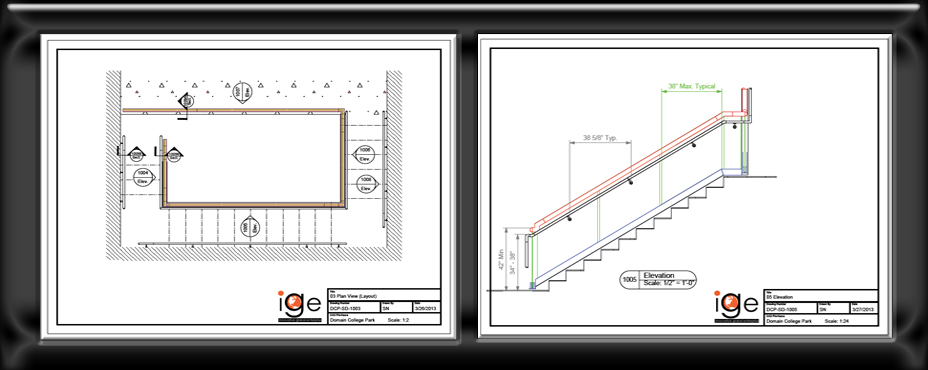

One of the most challenging yet fun projects we have completed so far! The job had a quick 4-week turnaround time from shop drawings to field installation. This is unheard of in this industry but we were able to execute and achieve.

John Johnson, VP – Field Operations, IGE

The installation took a full week of us working over-time but the end product looks great. No-one would believe if we said we did that in a week!

Enrique, IGE Employee

Railing installation is an art. It is not something any Joe-Shmo can do. There is a lot that goes into it. Everything has to be plumb, square, ground smooth, comply with codes.

Brett Howard, IGE Employee.

The shop drawings were done in a week but we still needed to go over all the mounting methods, complicated turns and transitions in the architectural as well as structural drawings. We had to be thorough with all the details so that we had no surprises when it came time for installation. We could not afford a delay due to minor oversights since building had to be move-in ready right away. Linda Cumerma, IGE Employee

- Custom-fabricated railings

- Design dictated by Architect

- Code-complaint superior construction

- Functional and elegant

- Fast and easy installation

The railings shop-drawings submittal package was completed in the less than week after being awarded the contract and field measurement shortly after. This submittal package was stamped by a MD licensed engineer to pass structural strength and other code compliance. The project is designed to the meet the International Building Code IBC 2006.

All the components used in this project were made from glass, aluminum and stainless steel including the anchors. The finish requested by the architect / designer was standard brushed finish on the stainless steel components. Glazing was clear and tempered per code.

The metal stringer was drilled and tapped to accommodate screws to attach the base shoe. The glass panels were attached using a no-mess dry-glazing method using compressed tapers. The handrail brackets, handrailing and toprail were installed shortly after.